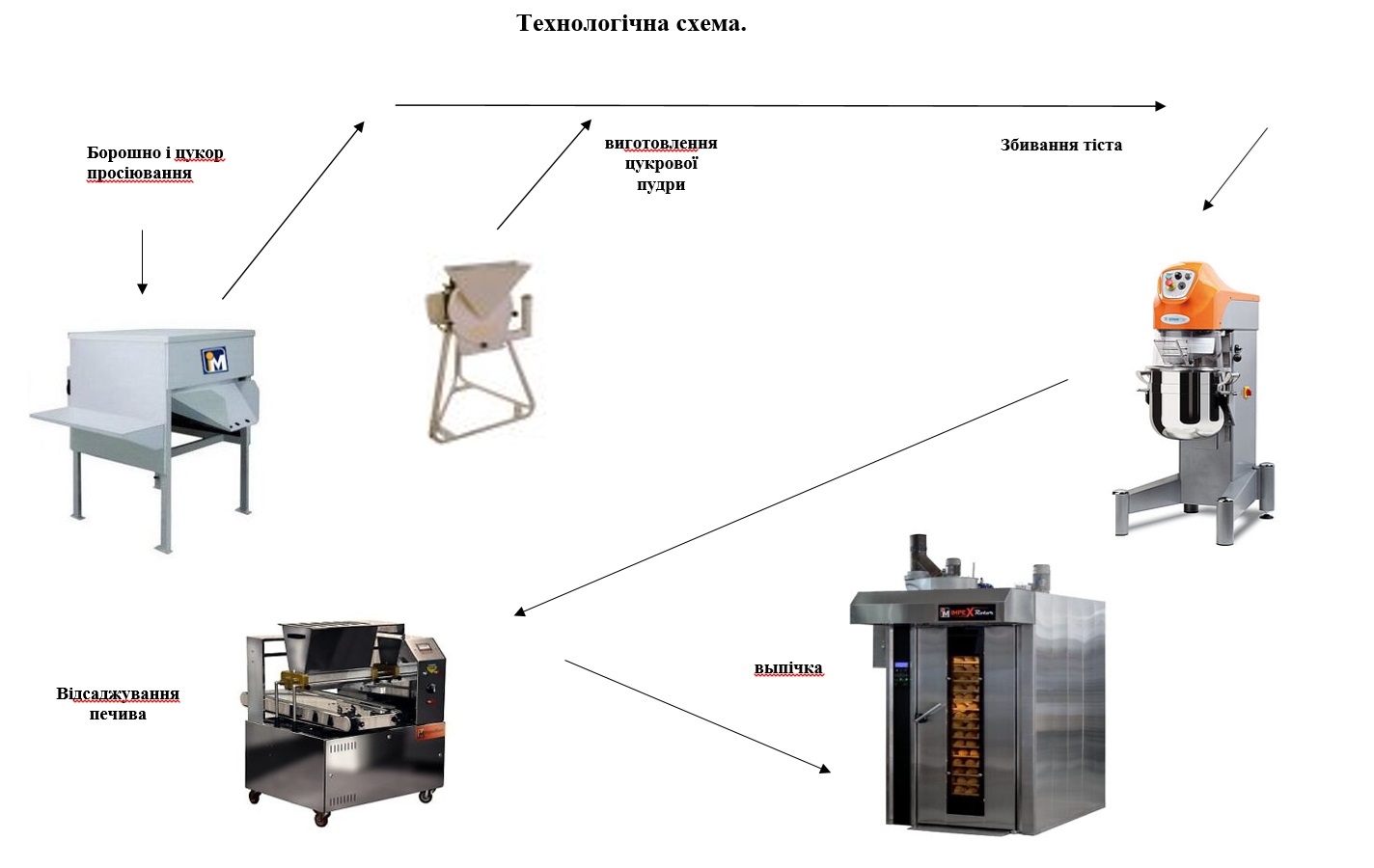

Shortbread cookies are baked from a liquid dough with a creamy consistency. The dough is prepared in a mixer. Butter (margarine) with powdered sugar is whipped for 10-15 minutes first at low speed, then at high speed, gradually adding the rest of the raw materials and, finally, flour. The resulting mass is mixed for 1-4 minutes at low speed. Depending on the form of deposition (manual or mechanized), the moisture content of the dough should be 15-24%. For mechanized planting – 21.5-23%.

The ready-made sand dough has the property of being stretched, so it is sent without delay to the formation in the depositing machine. The dough is loaded into the hopper, passes through the pumping shafts, then is squeezed onto the sheets through the nozzles. The shape of the cookies depends on the nozzles on the nozzles, as well as on the available functions and settings of the setting machine. The ImpexDrop-600 dropper features sheet pulling, nozzle rotation, and table raising and lowering functions, enabling the production of a significant number of cookie molds on a relatively small range of nozzles.

Cookies are baked at a temperature of 200-250 degrees for 3-8 minutes in a rotary or confectionery tunnel oven. After baking, the cookies should cool on the sheets, after which they are carefully removed with a scraper.

Cookies are decorated with jams and other fillings by a pastry dispenser-injector. A hose with a gun is attached to the Edhard dispenser, and fillings of various consistencies (from jams to boiled condensed milk) are dosed on the surface of the cookies or on the bottom (for further gluing). Shortbread covered with chocolate glaze is in great demand. A glazing machine is required for this. Glazing machine Impex EM-300 allows you to cover the product with glaze heated to 30-31 degrees from below, above, completely or half of the surface. Glazed cookies are cooled in the Impex CT-400.4 cooling tunnel at a temperature of 8-10 degrees and sent for packaging.

Technical data of the set

| Productivity, kg / h | 120-200 |

| Installed capacity, kW | 60 |

| Production area, square meters | 60-100 |

| Service personnel, person | 3-5 |

Functional composition

| Equipment | Quantity |

| Screener Impex FS-500 | 1 |

| Mini-mill for powdered sugar | 1 |

| Mixer Starmix PL60/ PL80 | 1 |

| Dropping machine ImpexDrop-600 | 1 |

| Rotary stove Impex Rotor (pellet, gas, electric, diesel) | 1 |

| Shelf trolley IR/22 4 | 4 |

| Floor sheet 600*400 (mm) 88 | 88 |